RECCS World Championship in spaghetti building

Rules

Version: 2.0

Valid from: 2022. 02. 22.

1. Rules for participating competitors of the World Championship

1.1. The World Championship is open to university teams. Team members need to be in active Bachelor (BSc) or Master (MSc) student status. The existence of the legal relationship with the University must be proved by a certificate issued in hungarian in the case of hungarian team and in english in the case of a foreign team and by certified by the educational institution.

1.2. The participating team can be accompanied by 1 teacher, but the teacher may not be actively involved in the construction of the structure.

2. Structure building and applying rules

2.1. Bridge Category

2.1.1. Material

- Pasta: commercially available or homemade pasta, made solely of flour (and eggs)

- Adhesive: any appropriate glue can be applied. The usage is restricted to element bindings at the joints. Strengthening the pasta by glue coating or gluing together the neighboring parallel threads is prohibited.

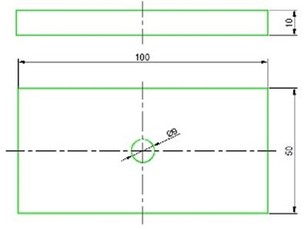

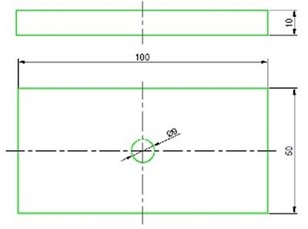

- Loading Platform: An 100mm x 50mm x 10 mm plate with a centrally drilled 9 mm bore. The loading force is introduced through an M8 eye bolt, placed in the bore. The eye bolt is fastened by a nut. The plate must not be altered in any way (for instance by boring), and it is to be glued only at the places joining the pasta threads.The loading platform is to be positioned under the pathway, in the middle of the bridge.

Figure No.1 Dimensions of the loading platform

2.1.2. Dimensions

- Distance between the highest (top) and the lowest (bottom) point must not exceed 600 mm.

- The bottom point must not be lower than 100 mm of the level defined by the points of the supports.

- The distance between the inner edges of the supports is 1000 mm, therefore the bridge has to be longer than that, but no longer than 1300 mm, and less than 130 mm in width.

- The total weight of the bridge (including the loading platform, the hook with the nut and the washer) must not exceed 1000 g.

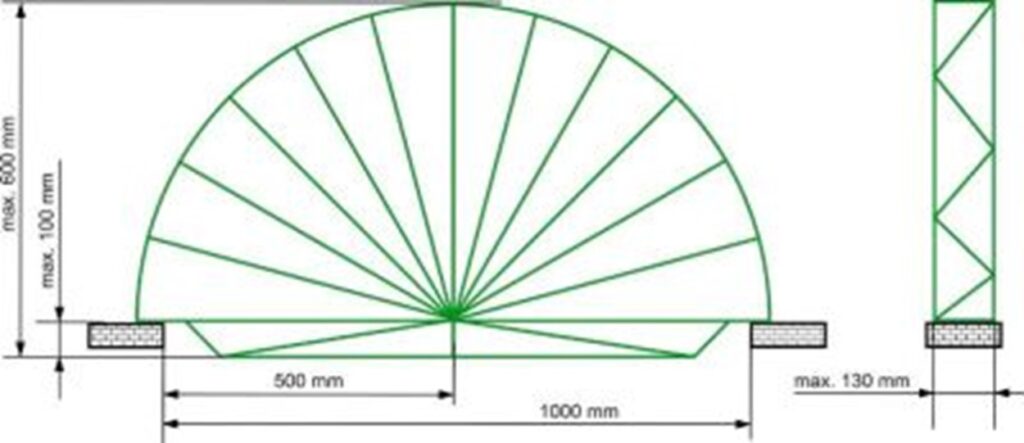

Figure No.2 Dimensions of the bridge and the place of the loading platform

2.1.3. Pathway

- The bridge must include a 50 mm wide pathway, stretching continuously between two end

- For pathway any appropriate pasta can be used (lasagne, wafer)

- It has to be within the distance closer than 50 mm to the plane defined by the supports

- A prismatic body of 50×50 mm in cross-section, and 100 mm in length must be able to be transported along the pathway

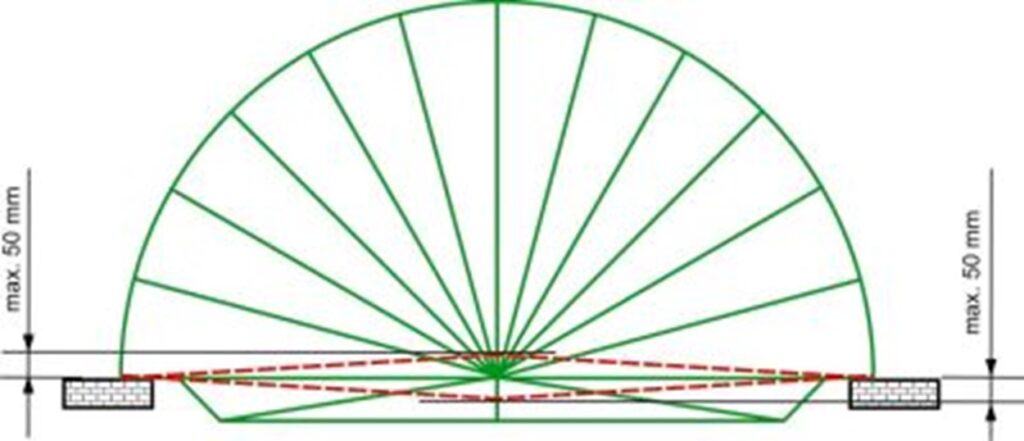

Figure No.3 The Position of the pathway on the bridge

2.1.4. Handing in the Bridge

- Checking the weight criteria of the bridge

- Checking the dimension criteria

- Ocular inspection of gluing

- Checking the pathway function

- Any failure in meeting of above conditions draws disqualification

- After the breaking, the bridge will be inspected to rule out any inside irregularity of the structure

- The structure must be weighed with screw,nut and washer.After the acceptance any modification is forbidden

- Manipulating the bridge afterwards with any materials (proofing,varnish, etc.) is not allowed

2.1.5. Applying the load

- The load is applied to the bridge by pulling the loading platform in vertical directiona híd terhelése középen, függőleges erővel történik

- The movement speed is 50 mm/min.

- The bridge is pulled until the bridge is broken

- The load capacity of the bridge is the weight, equivalent to the maximal force induced by the pull

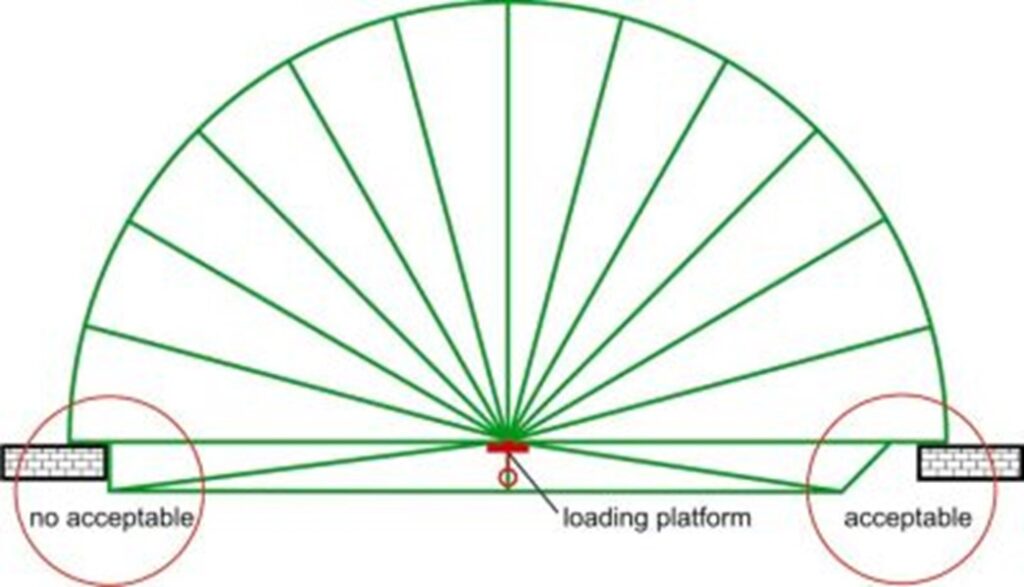

Figure No.4 Proper usage of supports

2.2. Support Category

2.2.1. Material

- Pasta: commercially available or homemade pasta, made solely of flour (and eggs)

- Adhesive: any appropriate glue can be applied. The usage is restricted to element bindings at the joints. Strengthening the pasta by glue coating or gluing together the neighboring parallel threads is prohibited.

- Loading Platform: An 100mm x 50mm x 10 mm plate with a centrally drilled 9 mm bore. The loading force is introduced through an M8 eye bolt, placed in the bore. The eye bolt is fastened by a nut. The plate must not be altered in any way (for instance by boring), and it is to be glued only at the places joining the pasta threads.

Figure No.5 Dimensions of the loading platform

2.2.2. Dimensions

- Distance between the highest (top) and the lowest (bottom) point must not exceed 600 mm.

- The bottom point must not be lower than 100 mm of the level defined by the points of the supports.

- The distance between the inner edges of the supports is 1000 mm, therefore the bridge has to be longer than that, but no longer than 1300 mm, and less than 130 mm in width.

- The total weight of the bridge (including the loading platform, the hook with the nut and the washer) must not exceed 1000 g.

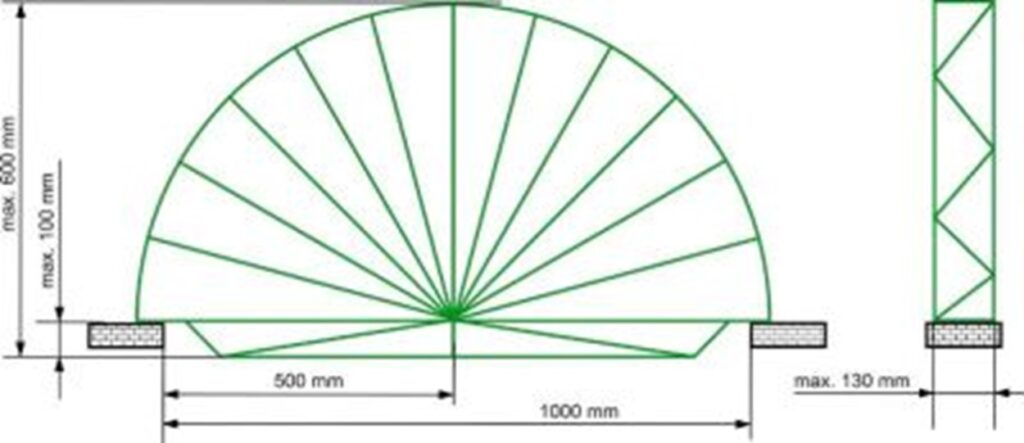

Figure No.6 Dimensions of the support and place of the loading platform

2.2.3. Handing in the Support

- Checking the weight criteria of the support

- Checking the dimension criteria

- Ocular inspection of gluing

- Any failure in meeting of above conditions draws disqualification

- After the breaking, the support will be inspected to rule out any inside irregularity of the structure

- The structure must be weighed with screw,nut and washer.After the acceptance any modification is forbidden

- Manipulating the support afterwards with any materials (proofing,varnish, etc.) is not allowed

2.2.4. Applying the load

- Supports can be used for holding vertical load forces only. Horizontal support is unacceptable

- The load is applied to the support by pulling the loading platform in vertical direction

- The movement speed is 50 mm/min

- The support is pulled until it is broken

- The load capacity of the support is the weight, equivalent to the maximal force induced by the pull

Figure No.7 Proper usage of supports